Shop made sanding block to chamfer the cut edge of the door make a sanding block by cutting a 2 by 3 4 inch strip of wood 1 2 inch shorter than the diameter of the peel and stick sanding paper for your random orbit sander.

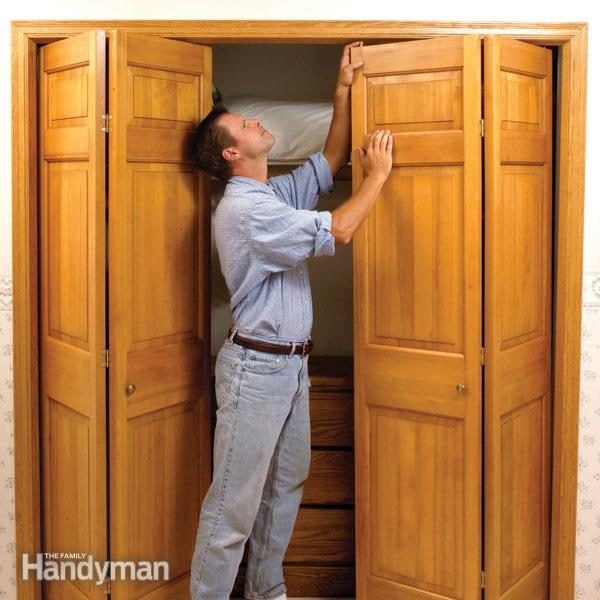

Cutting bottom of bifold doors.

Hence the need to cut.

I assume this as bifold openings tend to be slightly bigger if that is the case why not just put in standard doors that should fit.

Bevel the edges slightly to give the bottom a nice finish.

How to cut the bottom of a hollow interior door without damaging it.

Sand the bottom edge slightly with 100 grit sandpaper.

Both the bottom and the sides of the door needed to be trimmed.

Ancient post but this is one of the top hits when googling trimming a bi fold door.

I purchased a 36 wide hollow core bifold door to match the other doors in the room.

Step 4 cut the door from the back.

Hollow interior doors consist of a solid wooden frame covered with a wood or composite veneer.

Glue and clamp but if i need to hang the doors quicker i will shoot a couple brads in the peice to hold it til the glue dries.

I wouldn t use the door til the glue dries but you can atleast put it back on.

If you go with cutting the bifold i suggest after you get the pivots in and the door all hung right that you remove the bottom pivot and pump in a gob a construction adhesive and push the.

The doors are often used for.

The smallest of these three measurements is the reference you need for cutting your door to size.

If you decide to cut off an exterior door make sure you have a plan for sealing the bottom of the door against the threshold when the door is closed.

Measure the door frame at each corner and through the middle from the bottom edge of the jamb header to the floor or to the top of the threshold for exterior doors.

If this doesn t prove sufficient to allow you to remove the door from the frame gently wedge a pry bar underneath the base of the door and remove the bottom pivot first.

This is a hollow core composite door meaning that it s essentially a mdf frame covered in molded hard board with a few pieces of styrofoam stuck in between it to keep the hard board from collapsing in on itself.

Adjust both the top and bottom pivots to allow the most slack for the door.

Set the door down lengthwise on a work table.

You can check yourself by peeking in through the holes for the pivots.